Laminators are essential tools in both professional environments and personal projects, preserving documents and enhancing their appearance. With advancements in technology, laminators have evolved, offering various features, including the versatile dual-setting laminators. This guide explores the different types of laminators, focusing on their functionalities, applications, and how to choose the right one for your needs.

Understanding Lamination

Lamination involves encasing a document or material between two layers of plastic film, securing and protecting it. This process not only preserves the material but also enhances its stiffness, durability, and appearance. Laminators are widely used in schools, offices, and by hobbyists for projects ranging from preserving important documents to creating teaching aids and crafts.

Types of Laminators

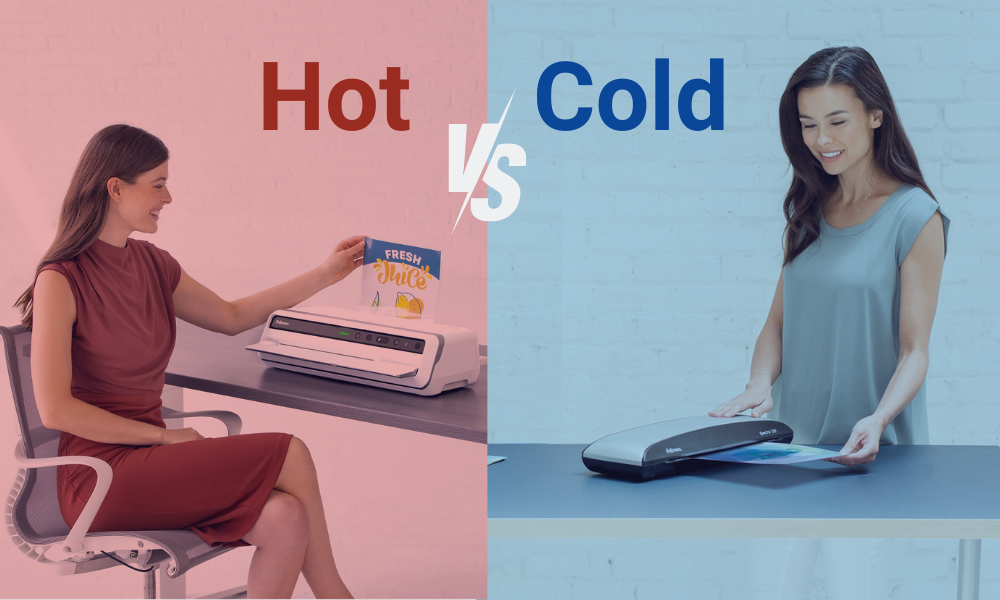

Laminators come in primarily two types: hot and cold. Each serves different needs based on the material being laminated and the desired outcome.

Hot Laminators

Hot laminators use heat to melt adhesive on the laminating film, bonding it to the material. They are ideal for materials that are not sensitive to heat, offering a durable and permanent seal. However, they require a warm-up time and caution to prevent burns, making them less suitable for quick tasks or with heat-sensitive materials.

Pros:

- Provides a strong, permanent bond.

- Typically offers a smoother, clearer finish.

- Better suited for high-volume laminating tasks.

Cons:

- Not suitable for heat-sensitive materials like thermal paper or certain photographs.

- Requires a warm-up period, delaying immediate use.

- Higher risk of burns or heat-related accidents.

Cold Laminators

Cold laminators, on the other hand, use pressure to bond the laminating film to the material. They are the go-to choice for heat-sensitive documents, such as photographs or inkjet-printed materials. Cold laminators are generally safer and simpler to use, eliminating the risk of burns and often requiring no electricity, but may not provide as durable a seal as hot laminators.

Pros:

- Perfect for heat-sensitive materials, ensuring their integrity remains intact.

- Ready for immediate use, ideal for quick lamination tasks without delay.

- Reduced risk of burns and heat-related accidents, enhancing overall safety.

- Many models do not require electricity, offering portability and energy savings.

Cons:

- The lamination might peel or come apart easier than with hot methods.

- Might not work as well on thicker materials or heavy-duty projects.

- Can sometimes leave bubbles or imperfections in the lamination.

- The finish might not be as smooth or clear.

Dual-Setting Laminators

Dual-setting laminators offer the best of both worlds, capable of switching between hot and cold lamination. This versatility is perfect for users who work with a variety of materials and need the flexibility to adjust the laminating method accordingly.

When to Use the Cold Setting on a Laminator

The cold setting is particularly useful for materials that could be damaged by heat, including photographs, vinyl, and certain types of inkjet-printed documents. It's also a safer option in environments with children or for quick lamination needs where waiting for a device to warm up is not practical.

Choosing the Right Laminator

When selecting a laminator, consider the following key factors to ensure you make an informed decision tailored to your specific needs:

- Frequency of Use: If you plan to laminate items regularly, invest in durable, quick-heating models designed for frequent use.

- Material Sensitivity: For heat-sensitive materials, a cold laminator or a dual-setting model is essential to prevent damage.

- Volume and Speed: High-volume environments benefit from fast-heating, efficient hot laminators, while occasional users might prefer the simplicity of a cold laminator.

- Budget Constraints: Cold laminators and manual models tend to be more budget-friendly, but investing in a dual-setting laminator can provide greater versatility and long-term value.

Laminator Techniques and Best Practices

Using a Hot Laminator:

- Preparation: Allow the laminator to fully preheat to ensure a consistent, smooth lamination process.

- Pouch Selection: Use the appropriate pouch thickness for your material, considering the laminator's specifications. Check out our selection of laminating pouches in various sizes and thicknesses.

- Feeding: Feed the pouch carefully into the laminator, ensuring it's aligned and the sealed edge enters first to prevent jams.

Using a Cold Laminator:

- Material Prep: Ensure your materials are clean and free from dust or debris before laminating.

- Pressure Application: Apply even pressure across the material as it feeds through the laminator to avoid bubbles and ensure a firm bond.

- Multiple Passes: For thicker materials, multiple passes through the laminator may be necessary to achieve a secure seal.

Best Practices:

- Test Runs: Conduct a test run with a similar material to adjust settings and ensure optimal results.

- Material Prep: Ensure your materials are clean and free from dust or debris before laminating. For a smooth lamination process, consider using our high-quality laminating films.

- Maintenance: Regularly clean your laminator's rollers to prevent adhesive buildup and ensure smooth operation.

- Proper Storage: Store laminating pouches and film in a cool, dry place to prevent warping and sticking.

Conclusion

Choosing the right laminator involves understanding the differences between hot, cold, and dual-setting laminators. Consider your specific needs, the materials you'll be laminating, and the frequency of use to make an informed decision. Whether you opt for a hot, cold, or dual-setting laminator, proper use and maintenance will ensure your documents are preserved and presented in the best possible way.

Experience Our Legacy in Paper Handling Equipment:

With decades of expertise in the industry, we are your trusted partner in identifying the perfect paper machines that aligns with your unique operational needs. You can reach out to us by filling the Contact form or call us at (800) 992-5279.